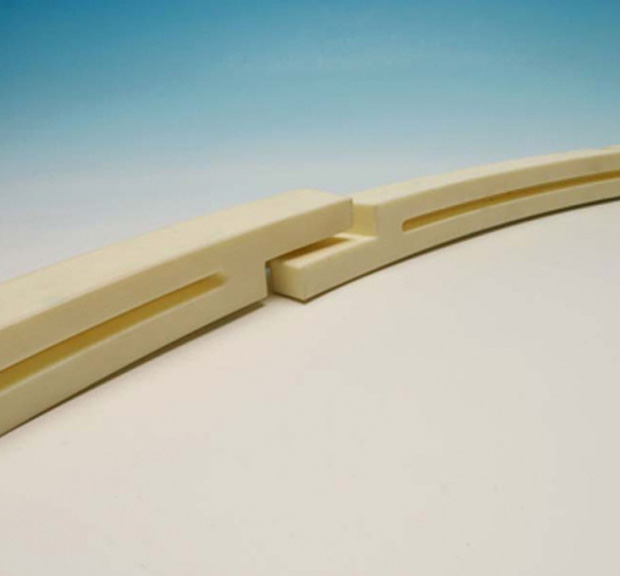

The Thordon SXL segmented seal has an excellent record of replacing segmented seals made of carbon and phenolic materials with many successful examples of their use for reference.

Thordon axial and radial seals last longer and reduce life cycle costs compared to other materials.

Main characteristics:

The operating parameters for the Thordon SXL segmented seals in terms of pressure and minimum leakage are generally speaking similar to traditional carbon or phenolic seals.

Thordon SXL segmented seals are designed for shafts of up to 2000 mm in diameter. They can be designed for use as a radial or axial seal.

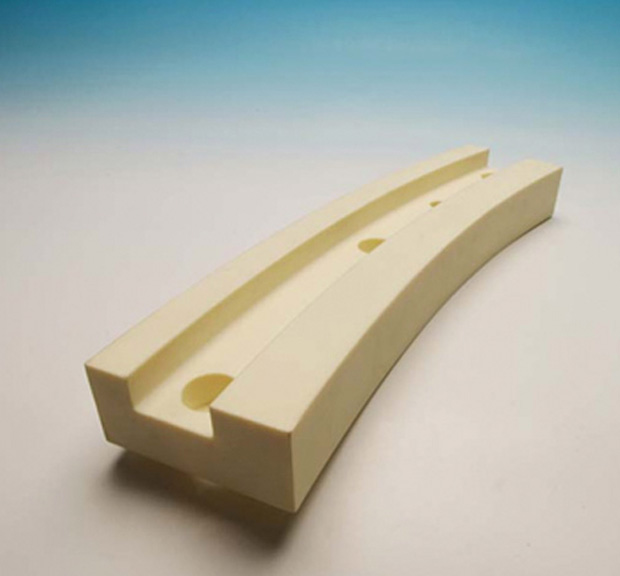

The segmented seal of the main shaft of a turbine normally operates with exposure to high PV conditions and to abrasive water. For this reason, the Thordon SXL seal is a benchmark solution for working in both clean and abrasive water.

The seal can be installed either in the upper or lower part of the main guide bearing, depending on whether it is a bearing lubricated with water or oil.

Custom designs are produced for optimum seal work based on the diameter of the shaft and the pressure.